We deliver premium trims and accessories with fast turnaround, competitive pricing, and world-class standards.

SAJ COMPANY PROFILE SAJ Catalogue Item Chart.pdfSAJ ACCESSORIES BD is your quality garments accessories manufacturer looking for highest support through integrity, teamwork &Innovation. Besides that world class machineries for accessories manufacturing, accelerate our strength provide you finest quality products. Our products line include different types of plastic items ( Stopper, Toggles, Beads, Buckle, Adjuster, bullet tipping, Hanger/hook with DTM, Screen Printed and Rubber coated color, Drawstring, Drawcord, Shoe lace, String Puller, Rubber Puller, Elastic, Twill tape, Leather and Silicon Patch, Metal Button, RF Label Tag, AM/DR Label Tag, Hard Tag. Our company specializes in providing a fast, professional and flexible one-stop solution to corporate customers from garment accessories types industries. We are able to provide services starting from product inquiry, Consultation, technical support to manufacturing, and even can produce custom-made product base on customer requirements. We successful set up Bangladesh factory in 2022, our manufacturing factory cover around 5000 square-feet. Currently, our existing customers including some famous corporations such as ZXY International, SMS mode, Poeticgem, 4A Yarnd Dyeing, Debonair Limited, AJ Group, BD design, Smart Jacket, Nassa Group, Fun fatory and some famous fashion brands such as, George, Kappa, Okamoto, Decimer, Kon, Wulwurth, Adler, Zarra, Pull & Bear etc.. Customer is always our top priority. By achieving our mission with fast response, good quality and promised lead time, it is glad for us to win great support and praise from our customer. .

A jeans button, also called a tack button, is a sturdy, durable metal fastener, typically brass or nickel, designed to securely close the waistband and pockets of denim garments, like jeans,. These buttons consist of two parts—the decorative top and a metal tack or post on the back—that are joined together by hammering the tack through the fabric and into the button on a hard surface, providing a strong, long-lasting closure that withstands wear and tear.

Types and Construction

Tack Buttons:

The most common type for jeans, these use a two-part metal system where the tack is hammered through the fabric to secure the button.

Donut Buttons:

These feature a hole in the center and were popular during World War II for their metal-saving design, though less common on modern jeans.

Materials:

Jeans buttons are most frequently made from metals like brass, nickel, copper, iron, or stainless steel, often with an antique finish for a classic look.

Function and Purpose

Durability:

They are built to be sturdy and withstand the rigors of everyday wear on denim, which is a heavy and durable fabric.

Security:

The tack system provides a secure closure that keeps the garment fastened throughout the day.

Aesthetics:

Beyond their functional purpose, jeans buttons contribute to the iconic and authentic look of denim, serving as a design element and symbol of timeless fashion.

Customization:

Buttons can be customized to reflect personal style, with designs varying in color, material, and detailing to match different outfits and brands

A jeans button, also called a tack button, is a sturdy, durable metal fastener, typically brass or nickel, designed to securely close the waistband and pockets of denim garments, like jeans,. These buttons consist of two parts—the decorative top and a metal tack or post on the back—that are joined together by hammering the tack through the fabric and into the button on a hard surface, providing a strong, long-lasting closure that withstands wear and tear.

Types and Construction

Tack Buttons:

The most common type for jeans, these use a two-part metal system where the tack is hammered through the fabric to secure the button.

Donut Buttons:

These feature a hole in the center and were popular during World War II for their metal-saving design, though less common on modern jeans.

Materials:

Jeans buttons are most frequently made from metals like brass, nickel, copper, iron, or stainless steel, often with an antique finish for a classic look.

Function and Purpose

Durability:

They are built to be sturdy and withstand the rigors of everyday wear on denim, which is a heavy and durable fabric.

Security:

The tack system provides a secure closure that keeps the garment fastened throughout the day.

Aesthetics:

Beyond their functional purpose, jeans buttons contribute to the iconic and authentic look of denim, serving as a design element and symbol of timeless fashion.

Customization:

Buttons can be customized to reflect personal style, with designs varying in color, material, and detailing to match different outfits and brands

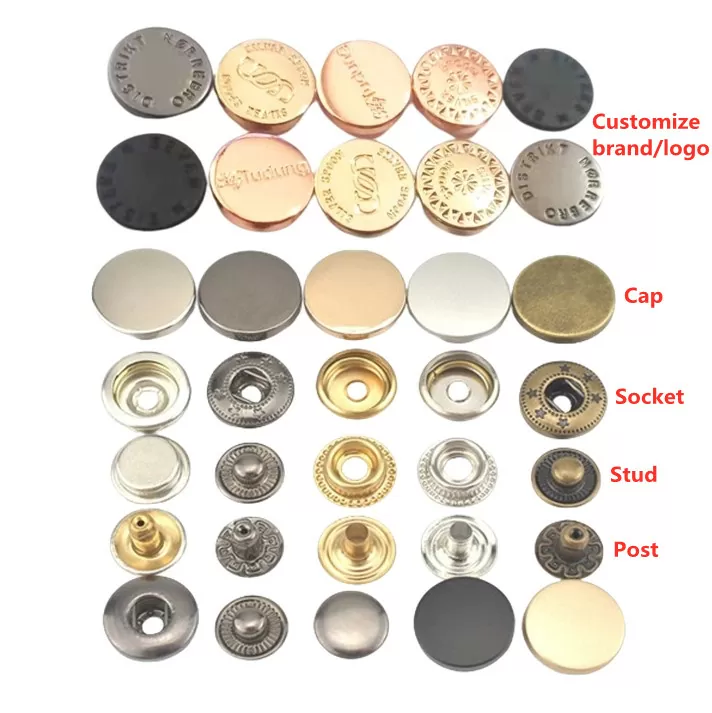

A snap button, also known as a snap fastener, is a two-part interlocking metal or plastic disc used to fasten clothing, bags, and other items together without sewing, often instead of a traditional button. It consists of a "stud" and a "socket" that fit together, creating a "click" or "snap" sound when fastened, making it easy to use and a popular choice for children's wear and baby clothes.

How they work

A typical snap fastener has four parts: a cap, a socket, a stud, and a post.

One piece has a circular lip or groove on its top surface, while the other has a matching projection.

These pieces interlock when pressed together, creating a secure closure that can be pulled apart with enough force.

Common uses

Clothing: Used on shirts, jackets, baby bodysuits, and jeans.

Bags and accessories: Found on purses, backpacks, wallets, and tote bags for secure closure.

Crafts and home decor: Used in fabric storage boxes or removable pillow covers.

Types of snaps

Sewn-on snaps: Two parts that are sewn onto the fabric.

No-sew snaps (riveted): Four parts that are riveted onto the fabric using tools like a hammer and punch.

Why they are used

Ease of use: They are quick and easy for children to operate, making them ideal for children's clothing.

Durability: They are a reliable and durable fastening option.

Convenience: They provide a strong and secure closure for various items.

A snap button, also known as a snap fastener, is a two-part interlocking metal or plastic disc used to fasten clothing, bags, and other items together without sewing, often instead of a traditional button. It consists of a "stud" and a "socket" that fit together, creating a "click" or "snap" sound when fastened, making it easy to use and a popular choice for children's wear and baby clothes.

How they work

A typical snap fastener has four parts: a cap, a socket, a stud, and a post.

One piece has a circular lip or groove on its top surface, while the other has a matching projection.

These pieces interlock when pressed together, creating a secure closure that can be pulled apart with enough force.

Common uses

Clothing: Used on shirts, jackets, baby bodysuits, and jeans.

Bags and accessories: Found on purses, backpacks, wallets, and tote bags for secure closure.

Crafts and home decor: Used in fabric storage boxes or removable pillow covers.

Types of snaps

Sewn-on snaps: Two parts that are sewn onto the fabric.

No-sew snaps (riveted): Four parts that are riveted onto the fabric using tools like a hammer and punch.

Why they are used

Ease of use: They are quick and easy for children to operate, making them ideal for children's clothing.

Durability: They are a reliable and durable fastening option.

Convenience: They provide a strong and secure closure for various items.

A prong snap button is a two-part fastener with a socket and a stud that features small "prongs" or teeth extending from the stud, which are then curled into the socket to secure it to fabric. Unlike traditional snaps, the prongs are visible on the underside after attachment, making it a "low-profile" design suitable for delicate materials like babywear and workwear because it minimizes fabric damage and offers excellent holding power. They are typically made of durable brass or stainless steel and are installed using specialized tools like hand presses or automatic machines with specific dies.

Key Characteristics

Two-part design:

A male part with prongs (the stud) and a female part with recesses (the socket).

Pronged attachment:

The prongs on the stud are curled into the socket to create a secure hold.

Low-profile:

The design is unobtrusive and creates a smooth finish on the fabric.

Minimal fabric damage:

Ideal for delicate fabrics due to its gentle attachment method.

Durable material:

Commonly made from brass or stainless steel for longevity.

Applications

Apparel:

Used on babywear, medical clothing, workwear, clipped shirts, and jeans.

Crafts and sewing:

Perfect for sewing projects and clothing repairs.

Installation

Specialized tooling:

Requires hand presses, automated machines, or special fastening molds.

Matching dies:

Dies specifically designed for prong snap buttons are recommended to ensure proper attachment

A prong snap button is a two-part fastener with a socket and a stud that features small "prongs" or teeth extending from the stud, which are then curled into the socket to secure it to fabric. Unlike traditional snaps, the prongs are visible on the underside after attachment, making it a "low-profile" design suitable for delicate materials like babywear and workwear because it minimizes fabric damage and offers excellent holding power. They are typically made of durable brass or stainless steel and are installed using specialized tools like hand presses or automatic machines with specific dies.

Key Characteristics

Two-part design:

A male part with prongs (the stud) and a female part with recesses (the socket).

Pronged attachment:

The prongs on the stud are curled into the socket to create a secure hold.

Low-profile:

The design is unobtrusive and creates a smooth finish on the fabric.

Minimal fabric damage:

Ideal for delicate fabrics due to its gentle attachment method.

Durable material:

Commonly made from brass or stainless steel for longevity.

Applications

Apparel:

Used on babywear, medical clothing, workwear, clipped shirts, and jeans.

Crafts and sewing:

Perfect for sewing projects and clothing repairs.

Installation

Specialized tooling:

Requires hand presses, automated machines, or special fastening molds.

Matching dies:

Dies specifically designed for prong snap buttons are recommended to ensure proper attachment

Metal accessories for garments are metal components, like buttons, rivets, and decorative studs, that are added to clothing for both practical functions, such as fastening and reinforcement, and aesthetic purposes, enhancing a garment's design, durability, and brand identity. These metal elements influence a garment's overall look and feel, adding value through their functionality and decorative qualities.

Types of Metal Accessories

Fasteners:

Metal Buttons: Used for closing garments and as decorative elements.

Snap Fasteners: Metal fasteners used for quick and easy closure.

Eyelets: Metal rings that reinforce buttonholes or lacing points.

Buckles: Used for adjusting or fastening straps and belts on garments.

Rivets: Cylindrical fasteners with a head, used for structural support or decoration.

Decorative and Functional Elements:

Metal Chains: Linked metal loops for decorative accents or as straps.

Metal Studs and Spikes: Small, decorative metal protrusions added to fabric for a unique texture and look.

Metal Logos and Labels: Customized metal plates or tags to display brand identity.

Cord Ends and Stoppers: Metal tips for drawstrings on hoodies or other garments.

Purpose of Metal Accessories

Functionality:

They provide essential functions like holding garments together, adjusting fit, and reinforcing stress points.

Aesthetics:

Metal accessories add visual interest, texture, and a sense of luxury or toughness to a garment.

Branding:

Custom metal logos, labels, and hang tags help establish a brand's identity and are used for promotion.

Durability:

High-quality metal accessories can contribute to the longevity and resilience of clothing.

Metal accessories for garments are metal components, like buttons, rivets, and decorative studs, that are added to clothing for both practical functions, such as fastening and reinforcement, and aesthetic purposes, enhancing a garment's design, durability, and brand identity. These metal elements influence a garment's overall look and feel, adding value through their functionality and decorative qualities.

Types of Metal Accessories

Fasteners:

Metal Buttons: Used for closing garments and as decorative elements.

Snap Fasteners: Metal fasteners used for quick and easy closure.

Eyelets: Metal rings that reinforce buttonholes or lacing points.

Buckles: Used for adjusting or fastening straps and belts on garments.

Rivets: Cylindrical fasteners with a head, used for structural support or decoration.

Decorative and Functional Elements:

Metal Chains: Linked metal loops for decorative accents or as straps.

Metal Studs and Spikes: Small, decorative metal protrusions added to fabric for a unique texture and look.

Metal Logos and Labels: Customized metal plates or tags to display brand identity.

Cord Ends and Stoppers: Metal tips for drawstrings on hoodies or other garments.

Purpose of Metal Accessories

Functionality:

They provide essential functions like holding garments together, adjusting fit, and reinforcing stress points.

Aesthetics:

Metal accessories add visual interest, texture, and a sense of luxury or toughness to a garment.

Branding:

Custom metal logos, labels, and hang tags help establish a brand's identity and are used for promotion.

Durability:

High-quality metal accessories can contribute to the longevity and resilience of clothing.

A plastic Stoppers, also known as a cord lock, is a small, spring-loaded fastener that uses a sliding mechanism to grip and adjust cords or drawstrings, allowing them to be tightened or loosened. Typically made of durable plastic, they feature one or more holes for the cord to pass through and a spring-activated internal clamp to hold the cord in place. These versatile components are widely used on apparel for hood adjustments, sportswear, bags, and tents to provide secure, easy-to-adjust closures.

A plastic Stoppers, also known as a cord lock, is a small, spring-loaded fastener that uses a sliding mechanism to grip and adjust cords or drawstrings, allowing them to be tightened or loosened. Typically made of durable plastic, they feature one or more holes for the cord to pass through and a spring-activated internal clamp to hold the cord in place. These versatile components are widely used on apparel for hood adjustments, sportswear, bags, and tents to provide secure, easy-to-adjust closures.

How it works

Thread the cord: The cord is threaded through the holes in the toggle button. Squeeze to adjust: The user squeezes the toggle to release the spring-loaded mechanism, which allows the cord to slide freely. Release to lock: When the squeeze is released, the spring clamps down, gripping the cord and holding it at the desired position.

Common uses

Clothing: Securing drawstrings on hoods of jackets, sweatpants, and other activewear.

Bags and accessories: Fastening drawstrings on gym bags, handbags, and backpacks.

Outdoor gear: Securing and adjusting cords on tents and other camping equipment.

Crafts: Used in various crafting projects, like scrapbooking, to secure cords

A plastic toggle button, also known as a cord lock, is a small, spring-loaded fastener that uses a sliding mechanism to grip and adjust cords or drawstrings, allowing them to be tightened or loosened. Typically made of durable plastic, they feature one or more holes for the cord to pass through and a spring-activated internal clamp to hold the cord in place. These versatile components are widely used on apparel for hood adjustments, sportswear, bags, and tents to provide secure, easy-to-adjust closures.

How it works

Thread the cord: The cord is threaded through the holes in the toggle button.

Squeeze to adjust: The user squeezes the toggle to release the spring-loaded mechanism, which allows the cord to slide freely.

Release to lock: When the squeeze is released, the spring clamps down, gripping the cord and holding it at the desired position.

Common uses

Clothing:

Securing drawstrings on hoods of jackets, sweatpants, and other activewear.

Bags and accessories:

Fastening drawstrings on gym bags, handbags, and backpacks.

Outdoor gear:

Securing and adjusting cords on tents and other camping equipment.

Crafts:

Used in various crafting projects, like scrapbooking, to secure cords.

A plastic toggle button, also known as a cord lock, is a small, spring-loaded fastener that uses a sliding mechanism to grip and adjust cords or drawstrings, allowing them to be tightened or loosened. Typically made of durable plastic, they feature one or more holes for the cord to pass through and a spring-activated internal clamp to hold the cord in place. These versatile components are widely used on apparel for hood adjustments, sportswear, bags, and tents to provide secure, easy-to-adjust closures.

How it works

Thread the cord: The cord is threaded through the holes in the toggle button.

Squeeze to adjust: The user squeezes the toggle to release the spring-loaded mechanism, which allows the cord to slide freely.

Release to lock: When the squeeze is released, the spring clamps down, gripping the cord and holding it at the desired position.

Common uses

Clothing:

Securing drawstrings on hoods of jackets, sweatpants, and other activewear.

Bags and accessories:

Fastening drawstrings on gym bags, handbags, and backpacks.

Outdoor gear:

Securing and adjusting cords on tents and other camping equipment.

Crafts:

Used in various crafting projects, like scrapbooking, to secure cords.

Plastic Buckles for Plastic Strap 1/2" - PACKSTRAP USAA plastic buckle is a clasp made from plastic material that fastens two ends of a strap, such as on a backpack, belt, or pet collar. These buckles are created through a process called injection molding, where molten plastic is injected into a mold and then cooled to solidify. They are known for being lightweight, rustproof, and durable, with common types including side release buckles for quick, one-handed operation.

How Plastic Buckles Work

Two-Part System:

Many plastic buckles, especially side release buckles, consist of two halves: a male component and a female component.

Interlocking Design:

The male part typically has a projection or latch that fits into a corresponding slot on the female part, creating a secure connection.

Quick Release:

A side release buckle is designed so that pressing a button or a specific area on the female part unlocks the male component, allowing the strap to be opened.

Common Types

Side Release Buckle:

A popular type that allows for quick and easy one-handed attachment and release of straps, commonly used on bags and backpacks.

Swivel Hook:

A rotating hook that connects to a strap and allows for flexible movement without tangling, used on lanyards or pet leashes.

Other Types:

Plastic buckles also come in various other forms, such as tri-glides and other adjustable buckles used with webbings, straps, and other adjustment mechanisms. .

Plastic Buckles for Plastic Strap 1/2" - PACKSTRAP USAA plastic buckle is a clasp made from plastic material that fastens two ends of a strap, such as on a backpack, belt, or pet collar. These buckles are created through a process called injection molding, where molten plastic is injected into a mold and then cooled to solidify. They are known for being lightweight, rustproof, and durable, with common types including side release buckles for quick, one-handed operation.

How Plastic Buckles Work

Two-Part System:

Many plastic buckles, especially side release buckles, consist of two halves: a male component and a female component.

Interlocking Design:

The male part typically has a projection or latch that fits into a corresponding slot on the female part, creating a secure connection.

Quick Release:

A side release buckle is designed so that pressing a button or a specific area on the female part unlocks the male component, allowing the strap to be opened.

Common Types

Side Release Buckle:

A popular type that allows for quick and easy one-handed attachment and release of straps, commonly used on bags and backpacks.

Swivel Hook:

A rotating hook that connects to a strap and allows for flexible movement without tangling, used on lanyards or pet leashes.

Other Types:

Plastic buckles also come in various other forms, such as tri-glides and other adjustable buckles used with webbings, straps, and other adjustment mechanisms. .

A plastic adjuster, also known as a ladder lock or slider buckle, is a small, durable plastic component used to easily adjust the length of straps on bags, backpacks, and other items. It works by allowing one end of the strap to pass through its internal structure, which can then be tightened or loosened to change the strap's length, making it a versatile tool for securing, tightening, or customizing straps for various light to medium-duty applications.

How it Works

Insert the Strap: The longer end of the strap is threaded under and over the internal bar of the plastic adjuster, with the bar becoming hidden inside the adjuster.

Secure the Strap: The opposite end of the strap is then secured by wrapping it around a separate piece of hardware, such as a rectangle ring.

Adjust Length: Moving the slider part of the adjuster up or down the strap allows the user to quickly and conveniently adjust the strap's length on the go.

Common Uses

Backpacks and Day Bags:

Commonly used to adjust shoulder straps for a comfortable fit.

Utility Straps:

Found on various utility straps that require periodic and convenient length adjustments.

Customized Tie-Downs:

Used in DIY projects and to create custom tie-down straps.

Bra and Lingerie Straps:

Also used on items like bras and swimsuits to adjust strap length.

A plastic adjuster, also known as a ladder lock or slider buckle, is a small, durable plastic component used to easily adjust the length of straps on bags, backpacks, and other items. It works by allowing one end of the strap to pass through its internal structure, which can then be tightened or loosened to change the strap's length, making it a versatile tool for securing, tightening, or customizing straps for various light to medium-duty applications.

How it Works

Insert the Strap: The longer end of the strap is threaded under and over the internal bar of the plastic adjuster, with the bar becoming hidden inside the adjuster.

Secure the Strap: The opposite end of the strap is then secured by wrapping it around a separate piece of hardware, such as a rectangle ring.

Adjust Length: Moving the slider part of the adjuster up or down the strap allows the user to quickly and conveniently adjust the strap's length on the go.

Common Uses

Backpacks and Day Bags:

Commonly used to adjust shoulder straps for a comfortable fit.

Utility Straps:

Found on various utility straps that require periodic and convenient length adjustments.

Customized Tie-Downs:

Used in DIY projects and to create custom tie-down straps.

Bra and Lingerie Straps:

Also used on items like bras and swimsuits to adjust strap length.

Advantages of Plastic Material.

Durability and cost-effectiveness: Plastic is a resilient and long-lasting material that is often cheaper to produce than alternatives.

Lightweight: The low density of plastic makes it ideal for applications where weight is a factor, such as in shipping.

Chemical resistance: Many types of plastic, such as polypropylene (PP), are highly resistant to chemicals, acids, and bases.

Safety: Plastic is non-toxic, making it safe for food and pharmaceutical applications, and can be used to create child-resistant closures.

Recyclability: While their environmental impact is a concern, many plastics used for stoppers are recyclable, aligning with sustainable practices

Polyester Flat Cotton Draw Cord Round Color Drawstring Cord ...Round drawstrings are cylindrical cords, while flat drawstrings are flattened or ribbon-like cords. Both are strings or ropes used to gather or tighten openings in clothing, bags, and other items, often made from materials like cotton, polyester, or nylon. Round drawstrings are common for hoodie hoods and shoelaces, whereas flat drawstrings are often found on joggers and activewear or for decorative purposes.

Round Drawstrings

Polyester Flat Cotton Draw Cord Round Color Drawstring Cord ...Round drawstrings are cylindrical cords, while flat drawstrings are flattened or ribbon-like cords. Both are strings or ropes used to gather or tighten openings in clothing, bags, and other items, often made from materials like cotton, polyester, or nylon. Round drawstrings are common for hoodie hoods and shoelaces, whereas flat drawstrings are often found on joggers and activewear or for decorative purposes.

Round Drawstrings

Features:

Round drawstrings Can have metal or plastic tips (aglets) at the ends to prevent fraying and make threading easier. while flat drawstrings Can be a blend with elastane for elasticity, and may feature woven patterns for style

Function:Both serve the same basic function of tightening fabric, but the choice of shape often depends on the application and aesthetic.

Round drawstrings are cylindrical cords, while flat drawstrings are flattened or ribbon-like cords. Both are strings or ropes used to gather or tighten openings in clothing, bags, and other items, often made from materials like cotton, polyester, or nylon. Round drawstrings are common for hoodie hoods and shoelaces, whereas flat drawstrings are often found on joggers and activewear or for decorative purposes.

Application:

Round cords are often seen as classic for hoods, while flat cords can offer a wider surface for designs or a more relaxed look on pants.

Woven elastic has a firm, horizontal-and-vertical-ribbed structure that makes it durable and non-rolling, ideal for heavier garments and waistbands. Knitted elastic, conversely, is softer and more flexible, created by knitting together yarn and rubber, allowing it to be sewn through without losing stretch and suitable for lighter wear like underwear and casual garments. Woven Elastic Structure : Woven elastic has a distinctive horizontal and vertical ribbed appearance due to its manufacturing process. Characteristics : It is very strong, durable, and resists stretching out over time. It is often referred to as "non-roll elastic" because its structure prevents it from rolling or folding. Uses : Best for heavy fabrics in outerwear, pants, and durable waistbands where a firm grip is needed. Knitted Elastic Structure : Knitted elastic is made from yarn and rubber in a flexible, looped structure. Characteristics : It is soft, flexible, and lightweight. A key feature is its ability to be sewn through directly without losing its stretch, making it versatile for different sewing applications. Uses : Ideal for garments requiring a gentle stretch, such as underwear, casual wear, belts, and sleeve cuffs. Key Differences Flexibility vs. Firmness : Knitted elastic is softer and more flexible, while woven elastic is firmer and more rigid. Stretch Recovery : Woven elastic has superior durability and a controlled stretch. Knitted elastic allows for greater freedom of movement and a more comfortable stretch. Sewing : Knitted elastic can be sewn through directly, whereas woven elastic is better for casings or when direct sewing isn't required. Woven elastic is a type of elastic band or webbing created by weaving fibers together, often incorporating rubber or synthetic fibers like polyester and latex, to provide both strength and elasticity. Characteristics: Durability and Strength: Woven elastic is known for its robust and durable nature, making it suitable for heavy-duty applications and ensuring it can withstand significant wear and tear. Shape Retention: It exhibits excellent shape retention due to its rigid construction, maintaining its elasticity even under stress. Minimal Stretch (compared to other types): While elastic, its stretch is often described as more controlled and less extensive compared to braided or knitted elastic, making it "non-roll". Applications: Heavy-Duty Items: Commonly used in industrial uniforms, straps for bags, belts, and other items requiring strong, resilient support. Garments: Frequently used for waistbands in heavier fabrics like jeans or chinos, as well as in upholstery and industrial textiles. Specialized Uses: Can be found in products like buttonhole elastic tapes for adjustable garments, equestrian equipment, and medical applications. Woven elastic is a type of elastic material characterized by its sturdy structure and the way its fibers are interlaced in a distinct warp and weft (horizontal and vertical) pattern, similar to how woven fabrics are made. It is often referred to as "no-roll" elastic because its firm construction prevents it from narrowing significantly when stretched and helps it maintain its width and shape even after repeated use or when sewn into a garment. Key Characteristics of Woven Elastic: Structure: Created by weaving strong and flexible yarns, typically synthetic fibers like polyester, nylon, or polypropylene, often combined with elastic threads like rubber or spandex, to form a durable and resilient tape. Durability and Strength: It is known for its high strength and ability to withstand significant stress and frequent use without losing its elasticity or shape. Stability: Maintains its width when stretched and doesn't easily roll or twist, making it suitable for applications requiring a stable and secure hold. Applications: Ideal for heavy-duty projects and medium to heavyweight fabrics, commonly used in waistbands of pants and skirts, outerwear, bags, industrial applications like safety harnesses, and medical devices. Sewing: Unlike some other elastic types, it can be sewn through lengthwise without significantly affecting its stretch and resilience, allowing for direct application to fabrics or use within casings.

Knitted elastic is a type of elastic material created by interlocking loops of synthetic or natural yarns, such as polyester, nylon, or cotton, using knitting techniques. It is known for its softness, flexibility, and ability to stretch and then recover its original shape. Characteristics: Soft and Smooth Texture: Knitted elastic is generally softer and more comfortable against the skin compared to other types of elastic like woven or braided elastic, making it suitable for garments worn close to the body. Retains Width When Stretched: Unlike braided elastic which narrows when stretched, knitted elastic maintains its width, offering consistent tension and a smooth appearance. Sew-Friendly: It can be sewn through directly without significant loss of stretch or resilience, making it versatile for various sewing applications. Good Recovery: It exhibits good recovery properties, meaning it returns to its original shape after being stretched, contributing to the longevity of the product. Light to Mid-weight Fabric Compatibility: It is well-suited for use with lightweight to medium-weight fabrics, although it may not offer the same firm grip needed for very heavy materials. Common Uses: Knitted elastic's comfort and flexibility make it a popular choice for: Clothing: Waistbands, cuffs, necklines in activewear, lingerie, swimwear, pajamas, and general apparel. Accessories: Hair ties, headbands, and decorative elements in craft projects. Home Textiles: Used in bedding such as sheets and mattress covers for a snug fit. Other applications: Footwear, orthopedic products (braces, bandages), and certain packaging applications.

Kalsi Cords | Everything about round elastic cordElastic cord is a type of stretchable rope made with a core of rubber or elastic fibers and a protective woven sheath of materials like polyester or nylon, designed to stretch and then return to its original shape. Valued for its strength, durability, and flexibility, it is used in diverse applications ranging from clothing and crafting to securing objects with bungee cords.

Construction

Core:

The inner material that provides the elasticity, typically made from rubber or spandex.

Sheath:

The outer layer of woven fibers (like polyester, nylon, or cotton) that protects the elastic core, enhances durability, and can be braided for a spiraling effect.

Key Properties

Stretchability:

The ability to be stretched to many times its original length and then revert to its original size.

Durability:

The capacity to withstand repeated tension without fraying, breaking, or losing its elastic properties over time.

Versatility:

Usable for a wide variety of tasks, including clothing, jewelry making, securing items, and more.

Common Types

Round Elastic Cord:

A common form used in jewelry and crafts, available in various diameters.

Flat Elastic Cord:

Another form, differing in shape from round cords.

Bungee Cords (or Shock Cords):

Heavy-duty elastic cords, often with hooks on the ends, used for securing cargo, luggage, and for activities like kayaking

Kalsi Cords | Everything about round elastic cordElastic cord is a type of stretchable rope made with a core of rubber or elastic fibers and a protective woven sheath of materials like polyester or nylon, designed to stretch and then return to its original shape. Valued for its strength, durability, and flexibility, it is used in diverse applications ranging from clothing and crafting to securing objects with bungee cords.

Construction

Core:

The inner material that provides the elasticity, typically made from rubber or spandex.

Sheath:

The outer layer of woven fibers (like polyester, nylon, or cotton) that protects the elastic core, enhances durability, and can be braided for a spiraling effect.

Key Properties

Stretchability:

The ability to be stretched to many times its original length and then revert to its original size.

Durability:

The capacity to withstand repeated tension without fraying, breaking, or losing its elastic properties over time.

Versatility:

Usable for a wide variety of tasks, including clothing, jewelry making, securing items, and more.

Common Types

Round Elastic Cord:

A common form used in jewelry and crafts, available in various diameters.

Flat Elastic Cord:

Another form, differing in shape from round cords.

Bungee Cords (or Shock Cords):

Heavy-duty elastic cords, often with hooks on the ends, used for securing cargo, luggage, and for activities like kayaking

Twill tape is a durable, flat woven ribbon characterized by a distinct diagonal rib or herringbone pattern, known as a twill weave. Made from materials like cotton, polyester, wool, or linen, it is used for reinforcing seams and edges, creating drawstrings or straps, and adding decorative details to clothing, crafts, and even industrial items. Its strong, flexible weave provides stability and resists fraying, making it a versatile and essential material in sewing and textile applications.

Key Characteristics

Weave Pattern:

Features a diagonal or v-shaped rib pattern (twill weave), which provides strength and stability.

Material:

Can be made from cotton, linen, polyester, wool, or blends of these materials, each offering different qualities like softness, breathability, or moisture resistance.

Form:

A flat, narrow fabric tape, sometimes referred to as a ribbon or webbing.

Properties:

Known for its durability, flexibility, and resistance to fraying.

Common Uses

Garment Construction:

Reinforces high-stress seams, waistbands, and edges, preventing stretching and tearing.

Finishing:

Used to bind edges of fabric to prevent them from fraying.

Fastenings:

Serves as sturdy ties for closing garments, like hospital gowns, and as components for drawstrings and straps.

Decoration:

Can be a decorative element on clothing and accessories.

Other Applications:

Also used in craft projects, packaging, and certain industrial or military applications.

Where to Find It

Twill tape is widely available at fabric and craft stores, from specialty ribbon suppliers, and through online retailers

Twill tape is a durable, flat woven ribbon characterized by a distinct diagonal rib or herringbone pattern, known as a twill weave. Made from materials like cotton, polyester, wool, or linen, it is used for reinforcing seams and edges, creating drawstrings or straps, and adding decorative details to clothing, crafts, and even industrial items. Its strong, flexible weave provides stability and resists fraying, making it a versatile and essential material in sewing and textile applications.

Key Characteristics

Weave Pattern:

Features a diagonal or v-shaped rib pattern (twill weave), which provides strength and stability.

Material:

Can be made from cotton, linen, polyester, wool, or blends of these materials, each offering different qualities like softness, breathability, or moisture resistance.

Form:

A flat, narrow fabric tape, sometimes referred to as a ribbon or webbing.

Properties:

Known for its durability, flexibility, and resistance to fraying.

Common Uses

Garment Construction:

Reinforces high-stress seams, waistbands, and edges, preventing stretching and tearing.

Finishing:

Used to bind edges of fabric to prevent them from fraying.

Fastenings:

Serves as sturdy ties for closing garments, like hospital gowns, and as components for drawstrings and straps.

Decoration:

Can be a decorative element on clothing and accessories.

Other Applications:

Also used in craft projects, packaging, and certain industrial or military applications.

Where to Find It

Twill tape is widely available at fabric and craft stores, from specialty ribbon suppliers, and through online retailers

Velcro tape is a reusable, two-part fastening system made of "hook" and "loop" strips that interlock when pressed together. The original patent was by George de Mestral, who coined the term "Velcro" from the French words for "velvet" and "hook". The tape is available with a peel-and-stick adhesive for smooth surfaces and as sew-on strips for fabric, and it can be cut to any length.

You can watch this video to see how Velcro works: Related video thumbnailFavicon YouTube • SewVeryEasy 23sHow it works

Two sides: Velcro tape consists of two strips: one with tiny, rough "hooks" and another with small, soft "loops".

Interlocking: When the two strips are pressed together, the hooks catch onto and cling to the loops, creating a strong bond.

Disengagement: The bond can be easily pulled apart, making it a reusable and temporary fastener.  Types of Velcro Tape

Types of Velcro Tape

Sticky-back tape:

This type has a peel-and-stick adhesive backing, making it ideal for securing lightweight objects to smooth surfaces like plastic, glass, or wood.

Sew-on tape:

This is a fabric-based fastener that is attached to materials using a needle and thread.

This is a fabric-based fastener that is attached to materials using a needle and thread.

Clothing and shoes:

For easy and quick fastenings.

Bags and accessories:

For securing closures.

Organization:

For hanging décor, labeling bins, and mounting items in homes and offices.

Industrial applications:

In healthcare, military, and automotive industries.

Leather patch Images - Free Download on FreepikA leather patch is a decorative or functional piece made of leather that can be attached to clothing, bags, or other items, often to display a logo, cover a stain, or add a unique design element. They can be applied using a heat-activated adhesive on items like hats or by being sewn or glued on. Leather patches can feature embossed, recessed, or laser-etched designs, and they are commonly used for branding, repair, or as a stylistic feature on products such as jeans, caps, and furniture.

Common Uses:

Branding and Advertising:

Businesses use leather patches on items like hats, bags, and apparel to promote their brand.

Repair:

Leather patches can be used to cover up holes, stains, or tears on furniture, bags, and other leather items.

Decoration and Style:

They add a premium and unique look to various products, from denim jeans to accessories.

How They Are Made and Applied:

Design:

Logos or designs are often created by hot stamping or laser etching to create raised or recessed areas on the leather surface.

Adhesive Application:

Some leather patches have a heat-applied adhesive backing that requires a heat press to bond securely to the item.

Other Attachment Methods:

Patches can also be sewn or glued directly onto the material.

Key Characteristics:

Durability:

When properly applied with heat, leather patches are durable and can provide long-lasting branding or repair.

Aesthetics:

They offer a classic and high-quality appearance, differentiating from other patch types like embroidered ones.

Material:

Patches can be made from genuine leather or faux leather, with varying textures and finishes

Leather patch Images - Free Download on FreepikA leather patch is a decorative or functional piece made of leather that can be attached to clothing, bags, or other items, often to display a logo, cover a stain, or add a unique design element. They can be applied using a heat-activated adhesive on items like hats or by being sewn or glued on. Leather patches can feature embossed, recessed, or laser-etched designs, and they are commonly used for branding, repair, or as a stylistic feature on products such as jeans, caps, and furniture.

Common Uses:

Branding and Advertising:

Businesses use leather patches on items like hats, bags, and apparel to promote their brand.

Repair:

Leather patches can be used to cover up holes, stains, or tears on furniture, bags, and other leather items.

Decoration and Style:

They add a premium and unique look to various products, from denim jeans to accessories.

How They Are Made and Applied:

Design:

Logos or designs are often created by hot stamping or laser etching to create raised or recessed areas on the leather surface.

Adhesive Application:

Some leather patches have a heat-applied adhesive backing that requires a heat press to bond securely to the item.

Other Attachment Methods:

Patches can also be sewn or glued directly onto the material.

Key Characteristics:

Durability:

When properly applied with heat, leather patches are durable and can provide long-lasting branding or repair.

Aesthetics:

They offer a classic and high-quality appearance, differentiating from other patch types like embroidered ones.

Material:

Patches can be made from genuine leather or faux leather, with varying textures and finishes

A silicone patch is a medical or cosmetic product made from medical-grade silicone that is applied to the skin to treat wrinkles, scars, and stretch marks. It works by creating a hydrating microclimate that traps moisture in the skin, which helps to soften, smooth, and reduce the appearance of these skin concerns over time. These patches are reusable, self-adhesive, and can be cut to fit different areas of the body.

How Silicone Patches Work

Moisture Retention:

The silicone patch creates an occlusive (airtight) layer on the skin, which prevents moisture from escaping and draws it from deeper layers to the surface.

Skin Rejuvenation:

This plumping and hydrating effect helps to refine lines and wrinkles, providing a smoother, more hydrated appearance.

Scar Healing:

By maintaining a moist environment, silicone patches promote the skin's natural healing process for scars. They can improve the scar's color, height, and texture, and relieve associated itching.

Collagen Production:

The process also increases blood flow and can help boost collagen production in the skin.

Uses of Silicone Patches

Facial Wrinkles:

Used to address frown lines, crow's feet, and forehead lines by providing hydration and reducing skin mobility.

Scars:

Effective for treating scars from surgeries, burns, C-sections, and keloids by softening and flattening them.

Stretch Marks:

Can be applied to areas with stretch marks to improve their appearance.

Key Features

Medical-Grade Material:

Made from skin-safe, medical-grade silicone.

Reusable:

Patches can be reused by washing the adhesive side with water, which restores their stickiness.

Adaptable:

Can be cut to fit the specific contours of different body parts.

Safe and Comfortable:

Designed to be comfortable to wear without causing irritation

A silicone patch is a medical or cosmetic product made from medical-grade silicone that is applied to the skin to treat wrinkles, scars, and stretch marks. It works by creating a hydrating microclimate that traps moisture in the skin, which helps to soften, smooth, and reduce the appearance of these skin concerns over time. These patches are reusable, self-adhesive, and can be cut to fit different areas of the body.

How Silicone Patches Work

Moisture Retention:

The silicone patch creates an occlusive (airtight) layer on the skin, which prevents moisture from escaping and draws it from deeper layers to the surface.

Skin Rejuvenation:

This plumping and hydrating effect helps to refine lines and wrinkles, providing a smoother, more hydrated appearance.

Scar Healing:

By maintaining a moist environment, silicone patches promote the skin's natural healing process for scars. They can improve the scar's color, height, and texture, and relieve associated itching.

Collagen Production:

The process also increases blood flow and can help boost collagen production in the skin.

Uses of Silicone Patches

Facial Wrinkles:

Used to address frown lines, crow's feet, and forehead lines by providing hydration and reducing skin mobility.

Scars:

Effective for treating scars from surgeries, burns, C-sections, and keloids by softening and flattening them.

Stretch Marks:

Can be applied to areas with stretch marks to improve their appearance.

Key Features

Medical-Grade Material:

Made from skin-safe, medical-grade silicone.

Reusable:

Patches can be reused by washing the adhesive side with water, which restores their stickiness.

Adaptable:

Can be cut to fit the specific contours of different body parts.

Safe and Comfortable:

Designed to be comfortable to wear without causing irritation

A rubber puller is a rubber handle or accessory designed to be attached to something to make it easier to pull or grip. The most common type is a rubber zipper puller, which enhances grip and ease of use for opening zippers on clothing, bags, and other items, especially in wet or cold conditions. Other types of rubber pullers are used to extract or hold objects, like seals and bearings in automotive settings, or to secure luggage with their flexible ropes and metal hooks. Purpose and Benefits Enhanced Grip: The flexible, often textured surface of a rubber puller provides superior grip, preventing slippage. Comfort: Rubber pullers are comfortable to hold, reducing strain during use. Durability: They are resistant to moisture, dirt, UV exposure, and wear and tear. Versatility: Rubber pullers are used in many applications, from everyday items like jackets to heavy-duty industrial equipment and automotive tools. Common Types of Rubber Pullers Zipper Pullers: Attached to zippers to improve operation and add a decorative element. Luggage Pullers: Used for securing luggage, consisting of elastic rubber ropes with metal hooks. Industrial Pullers: Heavy-duty rubber pullers for high-load applications. Automotive Pullers: Used for extracting press-fitted components like seals and bearings. Applications Apparel: Jackets, bags, and other clothing items. Outdoor Gear: Tents, backpacks, and luggage. Automotive: Extracting components or fixing moving parts. Industrial & Commercial: Heavy equipment and machinery.

Security tags are anti-theft devices, also known as Electronic Article Surveillance (EAS) tags, used in retail to deter theft and protect merchandise by triggering an alarm if removed improperly or passed through exit gates without deactivation at the point of sale. These tags contain electronic components that communicate with a store's EAS system, which includes pedestal antennas at exits and a deactivator at the checkout. Common types include acousto-magnetic (AM) tags and radio frequency (RF) tags, chosen for different merchandise and security needs. How Security Tags Work Tagging the Item: A small electronic chip or sensor is attached to the merchandise using a pin, adhesive, or a locking mechanism. EAS System: This tag is part of a larger Electronic Article Surveillance system. Pedestal Antennas: Pedestal antennas are installed at the store's entry/exit points. Alarm Activation: If a tagged item passes through these pedestals without being deactivated at the point of sale, the system detects the tag's signal and triggers an alarm, alerting staff to potential theft. Deactivation at Checkout: At the register, the tag is deactivated using a specialized detacher, which is a magnetic device that releases the locking mechanism, allowing the customer to leave with the purchased item without setting off the alarm. Types of Security Tags Acousto-Magnetic (AM) Tags: Known for their large detection range and resistance to interference, making them suitable for high-value items in department stores and electronics retail. Radio Frequency (RF) Tags: Operate at specific radio frequencies and are also widely used in retail environments. Electromagnetic (EM) Tags: Another type that functions on different electromagnetic principles. RFID Tags: These advanced tags can offer both theft detection and enhanced inventory management capabilities. Benefits Theft Deterrence: The most significant benefit is the prevention of shoplifting. Loss Prevention: They help reduce losses for retailers by protecting products from unauthorized removal. Inventory Accuracy: Some systems, particularly RFID, can also improve the accuracy of inventory management. Open Merchandising: By securing products without restricting access, they allow for the open display of merchandise, which can increase sales

detects the tag's signal and triggers an alarm, alerting staff to potential theft.

Deactivation at Checkout: At the register, the tag is deactivated using a specialized detacher, which is a magnetic device that releases the locking mechanism, allowing the customer to leave with the purchased item without setting off the alarm.

Types of Security Tags

Acousto-Magnetic (AM) Tags:

Known for their large detection range and resistance to interference, making them suitable for high-value items in department stores and electronics retail.

Radio Frequency (RF) Tags:

Operate at specific radio frequencies and are also widely used in retail environments.

Electromagnetic (EM) Tags:

Another type that functions on different electromagnetic principles.

RFID Tags:

These advanced tags can offer both theft detection and enhanced inventory management capabilities.

Benefits

Theft Deterrence:

The most significant benefit is the prevention of shoplifting.

Loss Prevention:

They help reduce losses for retailers by protecting products from unauthorized removal.

Inventory Accuracy:

Some systems, particularly RFID, can also improve the accuracy of inventory management.

Open Merchandising:

By securing products without restricting access, they allow for the open display of merchandise, which can increase sales

detects the tag's signal and triggers an alarm, alerting staff to potential theft.

Deactivation at Checkout: At the register, the tag is deactivated using a specialized detacher, which is a magnetic device that releases the locking mechanism, allowing the customer to leave with the purchased item without setting off the alarm.

Types of Security Tags

Acousto-Magnetic (AM) Tags:

Known for their large detection range and resistance to interference, making them suitable for high-value items in department stores and electronics retail.

Radio Frequency (RF) Tags:

Operate at specific radio frequencies and are also widely used in retail environments.

Electromagnetic (EM) Tags:

Another type that functions on different electromagnetic principles.

RFID Tags:

These advanced tags can offer both theft detection and enhanced inventory management capabilities.

Benefits

Theft Deterrence:

The most significant benefit is the prevention of shoplifting.

Loss Prevention:

They help reduce losses for retailers by protecting products from unauthorized removal.

Inventory Accuracy:

Some systems, particularly RFID, can also improve the accuracy of inventory management.

Open Merchandising:

By securing products without restricting access, they allow for the open display of merchandise, which can increase sales

Trusted by ZARA, Pull & Bear, George (ASDA), Kappa, Adler, Okamoto, and many more.

Email: sales@sajaccessoriesbd.com

Phone: +8801879921702 / +8801783596222